Why HVAC Efficiency Matters

Understanding the Cost of HVAC Inefficiency

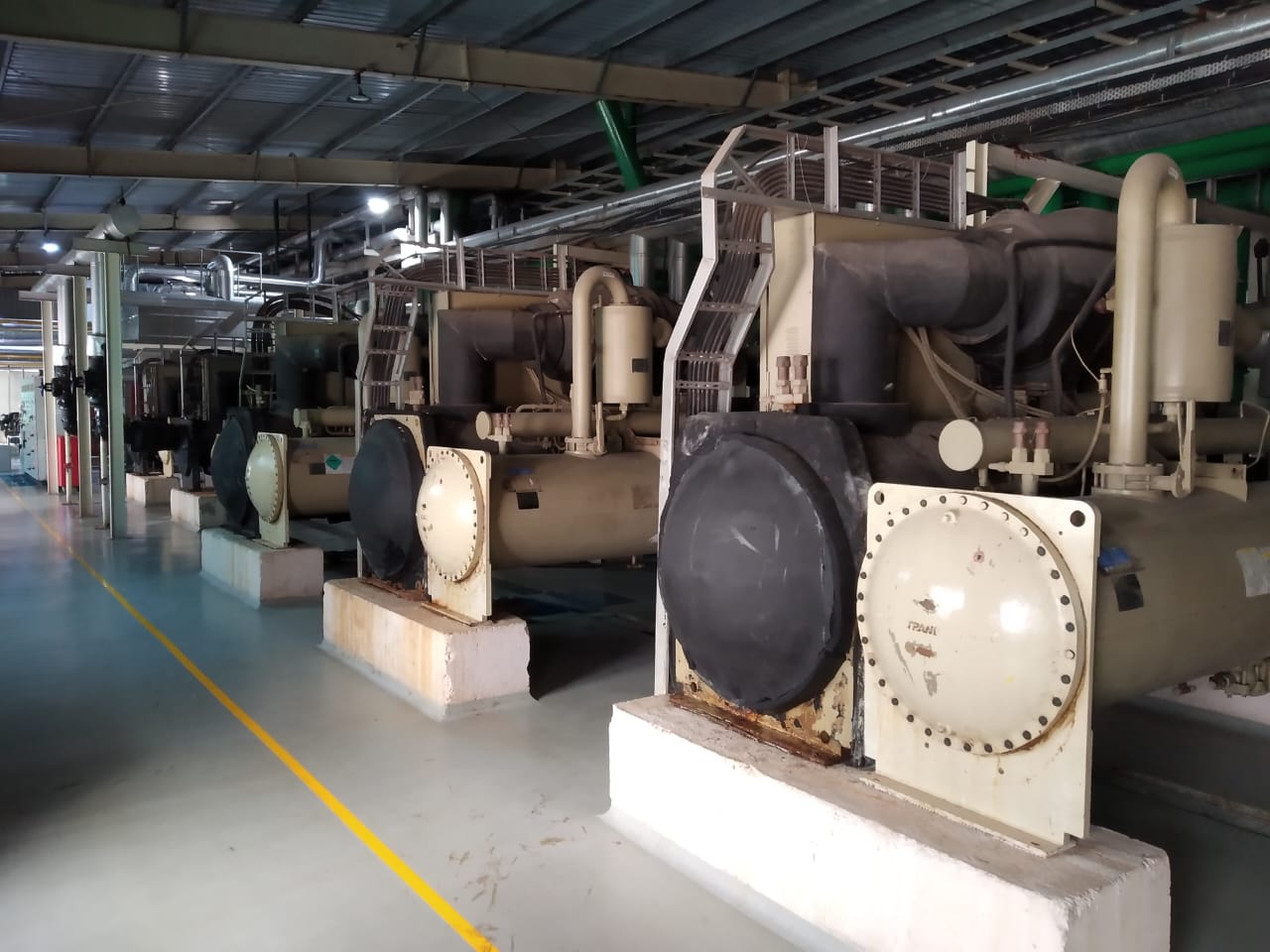

HVAC (Heating, Ventilation, and Air Conditioning) systems are the backbone of commercial buildings, industrial facilities, and data centres. However, a hidden efficiency killer—tube fouling—can significantly increase operational costs.

Studies show that even a thin layer of scale buildup (0.6mm) can reduce heat exchanger efficiency by up to 40%, leading to higher energy consumption (15-30% increase) and rising maintenance expenses.

🚀 Solution? Implementing Automatic Tube Cleaning Systems (ATCS) ensures uninterrupted heat exchange, cutting down energy waste and optimizing HVAC performance.

This article will explore how tube fouling affects your HVAC system and why an automated cleaning solution is essential for energy savings and sustainability.

The Science Behind Chiller Tube Fouling and Energy Loss

What is Tube Fouling in HVAC Systems?

Tube fouling is the accumulation of biofilm, scaling, sediment, and debris inside heat exchanger tubes of chillers. This buildup acts as an insulating layer, reducing the heat transfer efficiency and forcing the chiller to work harder, consuming more energy.

Common Types of Fouling in HVAC Systems

- Scaling: Caused by mineral deposits (e.g., calcium carbonate) from hard water.

- Biofouling: Microbial growth and biofilm formation on tube surfaces.

- Particulate Fouling: Suspended solids and debris accumulate over time.

- Corrosion Fouling: Oxidation-related deposits forming on tube interiors.

How Tube Fouling Impacts Energy Efficiency

- Increased Energy Consumption: Fouled tubes reduce heat exchanger efficiency, increasing chiller energy usage by 15-30%.

- Reduced Cooling Capacity: Fouling restricts heat dissipation, reducing the cooling system’s ability to maintain optimal temperatures.

- Higher Operational Costs: Increased energy bills and frequent maintenance cycles due to chiller inefficiency.

- Shortened Equipment Lifespan: Overworking HVAC components accelerates wear and tear, leading to premature failure.

🔎 Data Insight: According to the U.S. Department of Energy (DOE), HVAC systems account for 40% of a commercial building’s energy use. Even minor inefficiencies can lead to significant financial losses.

Traditional vs Automatic Tube Cleaning Methods

Limitations of Manual Cleaning, Chemical Descaling & Brushing System

Traditional HVAC maintenance relies on periodic manual cleaning and chemical descaling to remove deposits. However, these methods come with several downsides:

❌ System Downtime: Requires HVAC systems to be taken offline for maintenance.

❌ High Labor & Chemical Costs: Regular maintenance and chemical treatment expenses add up.

❌ Environmental Impact: Chemical descaling releases harmful byproducts into wastewater. ❌ Temporary Solution: Fouling starts accumulating immediately after cleaning.

Brush system: The brush system is a cleaning mechanism that removes fouling from tubes using brushes, but it comes with several drawbacks, including system downtime, reversed flow during cleaning, maintenance of the diverter valve, and increased pressure drop compared to the ball system.

How Automatic Tube Cleaning Systems (ATCS) Work

Automatic Tube Cleaning Systems (ATCS) are a game-changer in HVAC efficiency. These systems use soft cleaning balls injected into the chiller’s water circulation, preventing scale formation continuously and in real-time.

✅ Prevents fouling formation rather than removing deposits after they form.

✅ No downtime required, keeping chillers running at peak efficiency 24/7.

✅ Reduces energy consumption by 15-20%, cutting operational costs.

✅ Extends equipment lifespan and reduces maintenance frequency.

Business Case: ROI of Implementing ATCS in HVAC Systems

Cost Savings & Payback Period

Installing an Automatic Tube Cleaning System (ATCS) can lead to substantial financial benefits:

💰 Energy Savings: Up to 15-20% reduction in energy consumption. 💰 Lower Maintenance Costs: Eliminates frequent manual cleaning expenses. 💰 Payback Period: ROI achieved in 12-24 months based on energy savings and maintenance reductions.

Industry Applications Benefiting from ATCS

🏢 Commercial Buildings – Lower operational costs and improved tenant comfort. 🏥 Hospitals – Uninterrupted cooling ensures critical equipment performance. 💾 Data Centres – Prevents overheating and system failures. 🏭 Manufacturing Facilities – Consistent cooling optimises production efficiency. ⚗️Chemical/ Pharmaceutical –Avoiding costly shutdowns & supporting green initiatives

Sustainability & Compliance: Green Building Standards & ESG Goals

How ATCS Supports Sustainability Initiatives

- Reduces HVAC energy consumption, cutting carbon footprints.

- Lowers reliance on chemical descaling, reducing environmental impact.

- Supports compliance with LEED & ESG (Environmental, Social, and Governance) certifications.

🌱 Want to improve your ESG score? Upgrading to ATCS can help meet sustainability goals while optimising energy efficiency.

Conclusion: Future-Proof Your HVAC System with ATCS

HVAC inefficiency due to tube fouling is an expensive problem, but it’s preventable. By adopting Automatic Tube Cleaning Systems (ATCS), businesses can achieve:

✅ Lower energy bills ✅ Improved cooling efficiency ✅ Reduced maintenance costs ✅ Longer equipment lifespan ✅ Sustainability & ESG compliance

📞 Ready to optimise your HVAC performance? Contact us today to discuss how ATCS can benefit your facility!